Machines

Mastering electricity worldwide

Machines

Hardware for energy measurement purposes. ELEQ mastering electricity.

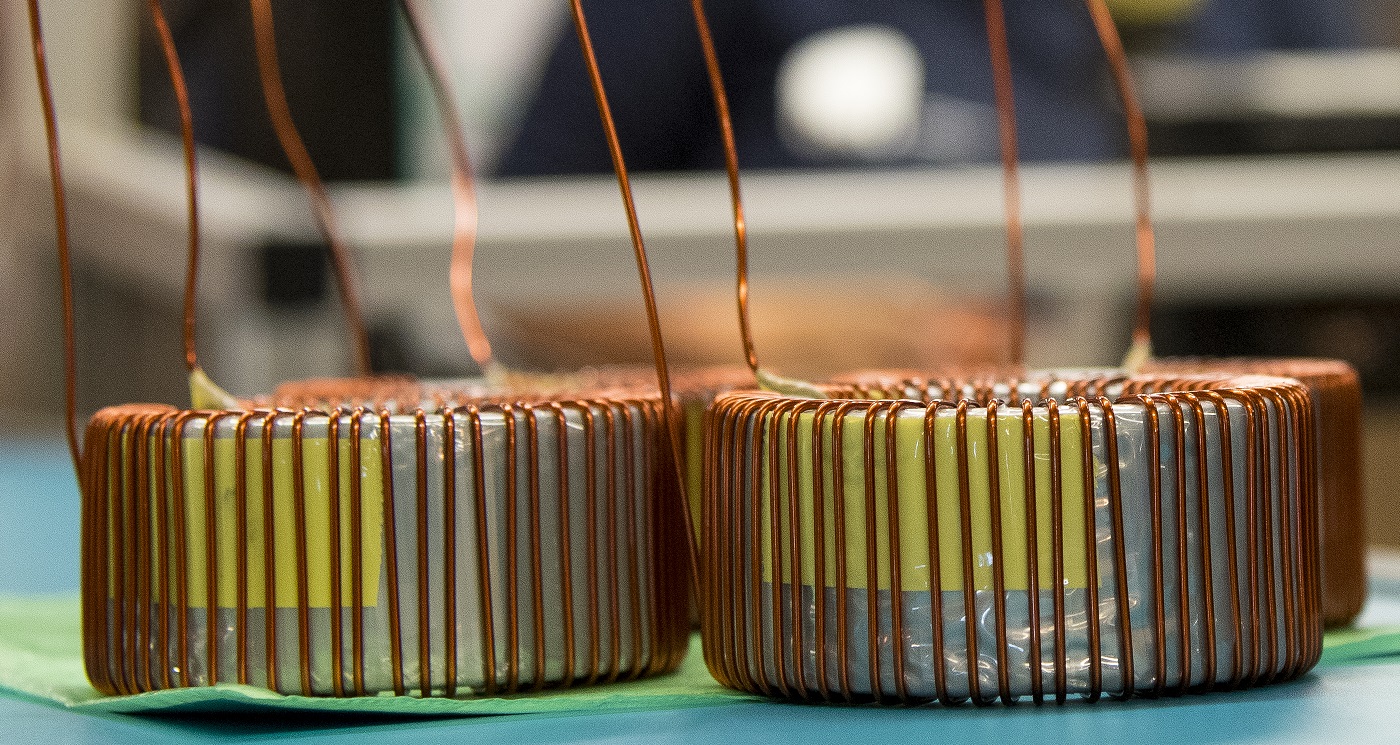

For more than 70 years now, ELEQ has been designing and manufacturing transformers and measuring equipment. Our products are compact, reliable and safe, the perfect solution for machines, because excellent energy quality is of utmost importance for machines.

We offer a standard line of analog measurement equipment and current transformers as well as customized to customer wishes. Custom-made wishes and a quicker developing market urges for quicker innovations on our behalf. We are perfectly able to respond to this, as we have our own Product Development Centre (PDC) to count on, as well as on our own production.

Specific application in the field of machines

Machines

Increased interest for energy measurement in machines

To save energy costs it could be very profitable to measure the usage of a machine. However, measuring the energy of machines not only result in less energy costs, also the measurement of energy can help to reduce standstill times and can enlarge the lifetime of a machine. Additionally, by measuring your energy you can produce on a more environmental-friendly machine To facilitate this ELEQ offers measuring equipment and current transformers.

Depending on market requests, we offer various standard possibilities, but also customized solutions to be used in machines.

Please feel free to contact us and ask for the possibilities in case you are looking for a custom-made solution for machine purposes.

Energy Management Line

Low voltage transformers

Analog measurement instruments

Process

From market and/or customer request to product

No matter what kind of questions you have, our specialized experts will surely find the correct solution for every particular situation. We consider each question as a challenge to arrive at the perfect result. Since we have our own Product Development Centre (PDC), this solution is more than just a rough drawing.

Within our PDC, we have an own designers team to prepare a detailed outline, a 3D printer allowing us to realise prototypes on the spot, a tool shop and a semi-finished products department. This allows us to be fully flexible to work out your solutions. At the semi-finished products department we are able to produce ourselves every screw or bolt needed for the solution. Besides, we also have an own extruding department. Next, we assemble the products by means of our automated manufacturing department. We also have testing devices, allowing us to test the products when needed before shipping them. From every transformer test reports could be consulted through our website. In short, our process from market and/or customer challenge to solution has become trusted within the electro-technical field thanks to ELEQ’s precision.

+31 (0)521 533 333

+31 (0)521 533 333

EN

EN  DE

DE  NL

NL